PET/PP Strap Production Line

Eco-model PET strapping extrusion line

Technical parameter:

Strap width | 9-32mm |

Production speed | 160m/min |

Stretching ratio | 4-6 |

Max.output | 200kg/h |

Product description:

PET strapping extrusion line : PET strap, also known as plastic steel band, which is used in place of steel on the world of a new environmentally friendly packaging materials, the development of new materials in recent years the cost of success and a substantial decline, have been widely used in the steel industry, chemical fiber industry, aluminum ingots, paper, brick kiln industry, screw industry, tobacco industry, electronics, textiles and wood, etc.; is replaced by a new high-strength steel strapping, is the world’s most widely used for steel products.

For users to save the cost of equipment purchases, especially on the initial investment of users, a large new R & D design light (economic type) PET packing belt production equipment, can achieve single one, a two belt production, production of up to 200kg/h.

Feature 1:

• The raw material processing and extrusion system

• High efficiency pre crystallization and drying system, the equipment can be used 100% bottles of recycled materials, the production of high value-added packaging belt.

• Special design of PET special screw, single and double screw extruder can be used to choose:

Feature 2: Double column exhaust type net changing device:

Feature 3:

• Embossing machine

• The hydraulic control can be set according to user requirements, embossing design, embossed with the synchronization control system, precise adjustment on the position of embossing roll and embossing strength.

Feature 4:

• Heat setting

• Special setting technology, to ensure that the rapid setting of belt products, to eliminate the back of the PET belt to remove the internal stress, to ensure that the belt size accuracy and quality.

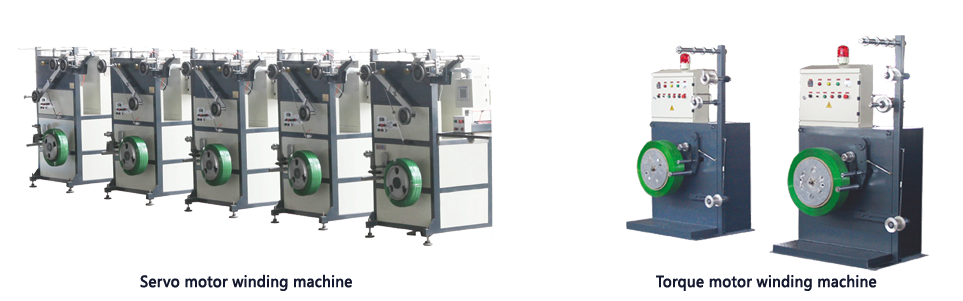

Feature 5: Servo winding machine and torque motor winding machine can choose: