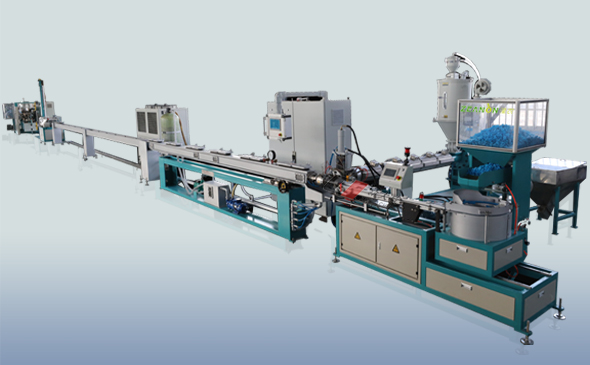

Drip Irrigation Pipe Production Line

High speed round dripper pipe production line

Technical parameter:

| Item | Pipe diameter | Pipe thickness | Production speed | Distance of dripper | Number of punched holes |

| High speed | Φ12-16-20mm | 0.5-1.5mm | 120-150m/min | 100-1000mm | 2、4 holes |

Product description:

Feature 1:

• Two layer Co-extrusion Technology & Mark colour line

• Adopt High-Efficient and Energy-saving extruder, stable plasticization of raw materials and large output.

• According to the user's choice, the double-layer co-extrusion extrusion system is used to improve the utilization rate of recycled materials, reduce the cost and ensure the service life of the drip irrigation pipe.

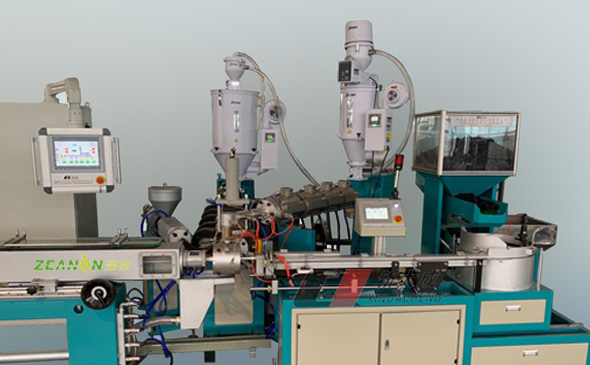

Feature 2:

• High-speed dripper screening and insertion system.

• Be used for identification and inserting Φ12-16-20mm round dripper.

• Inserting speed: 450-500pcs/min.

• With servo driving very precisely controlled dripper insertion system.

• Dripper screening, inserting, space are operated by PLC system.

Feature 3: Be used for identification and inserting round dripper, PC dripper of all length(optional).

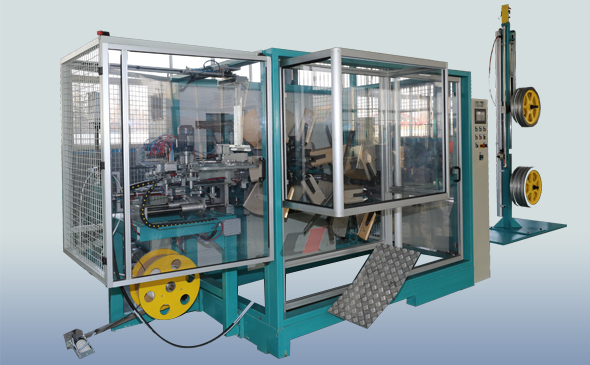

Feature 4:

• Automatic punching technology.

• Speed:450-500 pcs drilling/min.

• Used for driling double drip hole, four drip hole.

• Controlled by serco motor, to achieve precision drilling.

• Provide customer with remote support service.

Feature 5:

• Full automatic winder and strap pack, metering functionality.

• For pipe coiling, cutting, roll change, meter to realize full automation.

• Online automatic strap packing unit(optional).

• Machinery speed: 100m/min.

• If with online strap unit, machinery speed 120m/min.